Crushers are crucial in modern industries. Crushers have applications in the mineral processing industry, the aggregates industry, construction, and recycling. Increasing production needs and sustainability goals create the need for improved machines. In this regard, crusher manufacturers are focusing hard on efficient and innovative designs. Eastman Technology is a leader in this field. With 30-plus years of experience, the company has developed high-performing solutions. The Eastman's key focus includes innovation, precision engineering, and efficiency.

The Evolution of Crusher Manufacturing

Crushers have changed over the years. Early devices were driven by simple mechanical force. Today's systems combine automation, precision, and energy savings. Efficiency is not optional anymore. It reduces downtime, decreases energy consumption, and decreases the operating costs. Eastman started in 1985 with rock crushers. Over time, the company grew to offer turnkey crushing and screening solutions. This journey spans from mechanical tools to integrated advanced systems.

Science of High-Efficiency Fine Grinding

High-efficiency crushing is aimed at multiple performance indicators. Throughput, energy optimization, and particle size control are decisive. Wear resistance is also essential. Engineering design is at the core of this science. Efficient chamber designs, optimized rotational speeds, and high-strength alloys maximize performance. Performance and reliability optimization lead to long-term productivity and efficiency. At Eastman, we keep these principles in mind for all our designs, ensuring they are efficient without compromising safety.

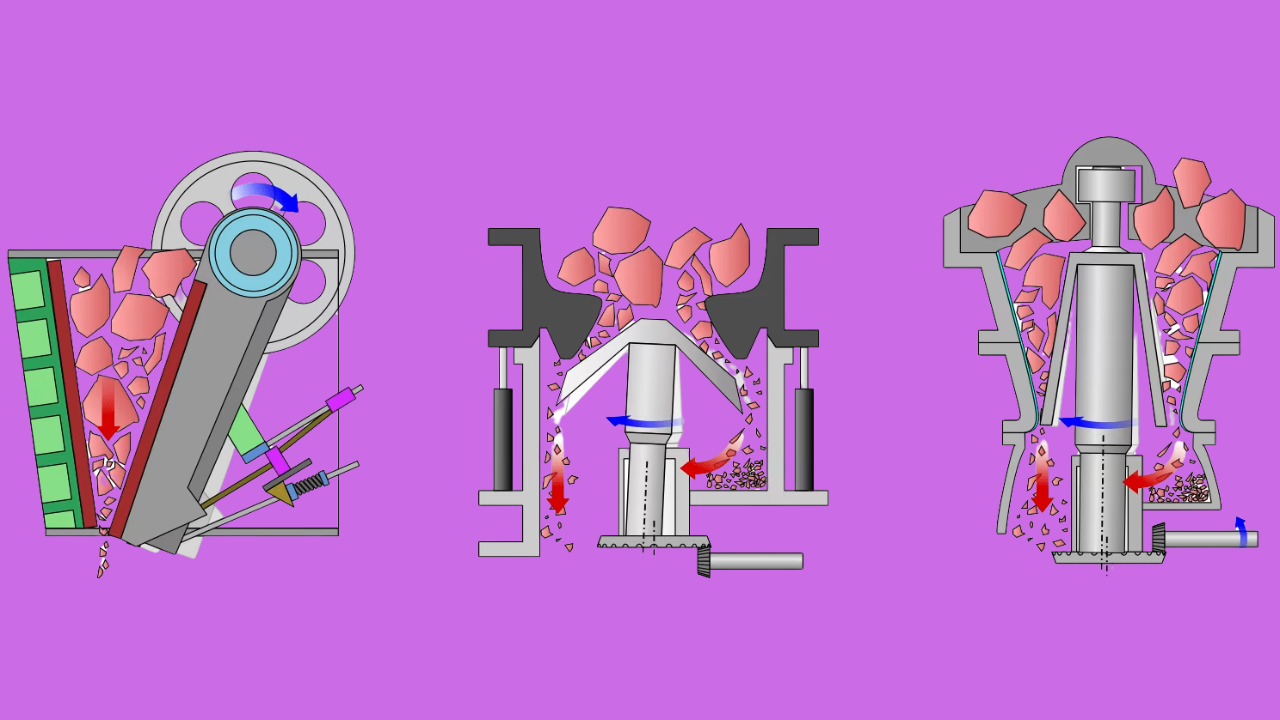

Equipment Range for Different Crushing Requirements

Eastman offers a diverse range of equipment. Each category covers a different industrial problem. Jaw crushers provide crushing strength in primary crushing. They enable durability and adaptability across a wide range of materials. Cone crushers are designed to achieve secondary efficiency. Impact and hammer crushers save energy in the crushing process. Mobile crusher plants allow flexibility and on-site mobility. VSI sand making machines can effectively make artificial sand. Vibrating screens, feeders, sand washers, and other auxiliary equipment ensure the smooth operation of the process. Together, this portfolio provides integrated and efficient crushing solutions.

Crushing Solutions for Industry Applications

Different industries require different solutions. In mineral processing, crushers are used to process ores, facilitating further grinding and processing. Aggregate production requires uniform particle sizes of high quality. Artificial sand making can help address the shortage of natural sand. VSI machines efficiently make high-quality sand. Construction waste recycling converts waste into reusable resources. Recycling crushers are a sustainable solution that conserves landfill space and reduces waste. The diversity of Eastman applications in these industries demonstrates the versatility of specialized equipment in solving various problems.

Mobility and Automation in the Crushing Plant

Today's operations require mobility. Portable and track-mounted units enable operations to go where they are needed. This adaptability enhances efficiency at dynamic work locations. Automation is an additional level of progress. Smart controls enhance safety, minimize errors, and optimize throughput. Eastman is a blend of old and new: traditional strength with modern automation. The result is equipment that is both strong and smart. Operators get better results while retaining operational control.

Material Engineering: Constructing Crushers for Durability and Reliability

Durability is another efficiency factor. Rugged engineering, long service life materials, and wear-resistant alloys reduce the number of maintenance cycles. Long-life components minimize downtime, thus keeping production up and running. All Eastman designs consider material strength. Machines are designed to operate in less favorable working conditions. This attention ensures reliability, reduces costs, and promotes long-term high performance.

How Continuous Innovation Can Power Efficiency Gains

Innovation is the catalyst for the evolution of crushers. The system remains efficient and effective through ongoing research and design improvements. Experience with field performance defines future designs. The current trend in the industry is towards energy-efficient motors, eco-design, and intelligent control systems. Eastman has been innovative since the beginning. Every upgrade signifies a dedication to efficacy and reliability. Continuous development ensures that equipment remains current with changing demands.

Future and Global Impact of High-Efficiency Crushing Solutions

Eastman expanded from local beginnings in China to worldwide prominence. The company's solutions span industries on different continents. Sustainability is entering crushing technology in a growing capacity. Design strategy is influenced by resource optimisation and the circular economy. The future holds the promise of AI-based automation, the integration of renewable energy, and sophisticated digital monitoring. Eastman is preparing to lead these changes. By integrating legacy engineering with future technologies, the company is poised to achieve the next level of industrial efficiency.

Conclusion

Crushers are the efficiency-determiners for most production processes. High-efficiency crushing increases profitability while being sustainable. Manufacturers are at the center of delivering such solutions. Eastman Technology, a company that has been operating since 1985, is an excellent example of a company operating at the forefront of this field. The company combines innovation, reliability, and a global presence to deliver value. Even more intelligent and environmentally friendly machines will be developed in the future. Efficiency is the driving force that determines the next generation of crushing solutions.